Release time:2025-04-09 15:35:36Clicks:author:SPG ArcheryMain categories:Bows, Arrows, Archery Accessories

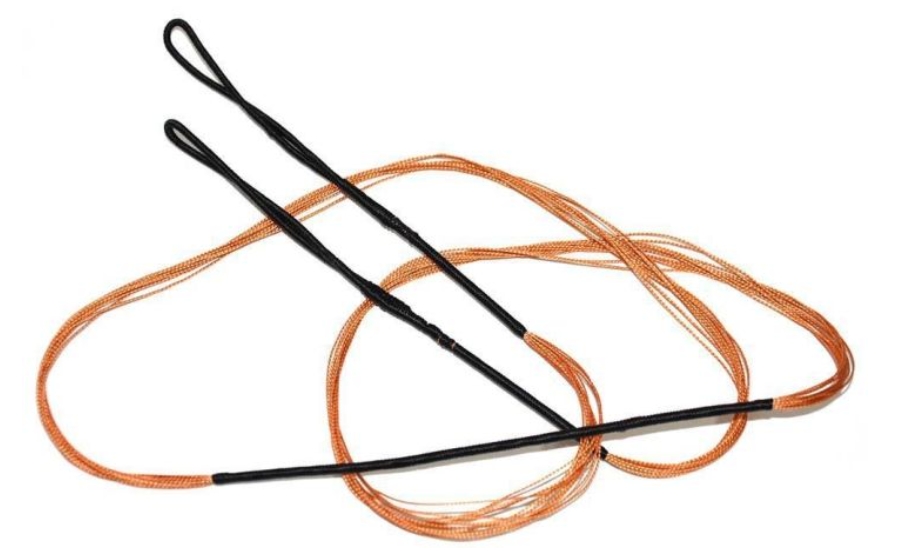

There are always people who say that compound bows will fuzz up after being worn and chewed. The general answer is to wax them. In fact, waxing cannot prevent the wear and tear of bowstrings, but only makes the worn parts look better. What is the use of waxing? Why wax? Most of the bowstrings we use are made of PE materials. Manufacturers wax the fibers during the production process, which means that the bowstrings are full of wax as soon as they are produced. Why do manufacturers add wax to the bowstring materials? What is the role of wax in bowstrings?

I have been playing compound bows for many years. Like a novice, I was entangled in the problem of bowstring wear and hoped to solve this problem. In fact, this problem cannot be solved. Bowstrings will wear and fuzz up when used. Even if they are not used, bowstrings have a lifespan. Bowstrings often reach the end of their service life and should be replaced before they are worn out and cannot be used. Later, I didn't bother about this problem much. I was used to wear and tear. This is also why few foreigners in foreign forums are entangled in the problem of plastic sliding splitters wearing bowstrings, and few foreigners wrap ropes around the sliding splitters. What is the role of string wax? My experience in the past few years is that it can extend the life of the bowstring and improve the stability of the compound bowstring. The composite bowstring is made of very thin PE filaments twisted together. During use, these filaments will rub and squeeze each other. String wax reduces this friction and greatly increases the life of each single filament, thus extending the life of the entire bowstring.

Because string wax fills the gaps between the bowstrings, various pollutants, organic solvents, various salts (sweat), and fine dust from the outside are difficult to enter the bowstring to damage the single filaments of the bowstring, which also extends the service life of the bowstring. It also makes the weight (quality) of the bowstring very stable, and will not be affected too much by precipitation or sweat. The accuracy (it is terrible if the bowstring is not waxed and full of sweat or rain in the top compound bow competition.) This also makes it possible to use the compound bow in an environment of minus ten degrees or even lower. If there is no string wax, the bowstring will freeze when it is stained with water, which is even more terrible. Dust entering the bowstring is like the bowstring filaments are slowly being worn and cut by various things, and the life span can really last for tens of thousands of arrows.

The wear of the sliding splitter on the bowstring is something that everyone often encounters. Regularly use string wax to clean these parts to remove the dust and reduce the wear of the dust on the bowstring. The friction between the bowstring and the splitter at the moment of releasing the arrow will generate a relatively high temperature. If the maximum tolerance temperature of PE should be around 140 degrees, although the tensile strength will gradually decrease with the increase in temperature, a large part of the heat generated by the friction between the bowstring and the splitter is absorbed by the string wax. Regularly and appropriately using string wax in this part can indeed reduce wear, but it cannot eliminate wear.